Precision Levelers are much better at removing coil set and crossbow than coil straighteners or coil flatteners. Precision Corrective Levelers can also eliminate coil shape defects that simple flatteners cannot remove.

Understanding the difference between a corrective leveler and a straightener is key when specifying what type of equipment is required for a certain job. A straightener will only correct for coil set and some cross bow as it has no adjustable back up rolls. Coils that have already been leveled and only have a memory from being wound up (coil set) within them can be corrected by utilizing a straightener and adjusting the head tilt based on material thickness. Coils that have other conditions such as edge wave or center buckle require the use of a corrective leveler to obtain flat material from these incoming coil conditions. A corrective leveler has power adjusted back up rolls to allow you to work the material in specified regions as required to flatten the strip. A coil that has edge wave requires the center of the strip to be worked and stretched to have the same length material as the outside edges. In center buckle applications just the opposite is required. The center of the material is longer than the edges. This requires that the edges of the material be worked to become the same length as the center and this results in flat material being obtained on the exit of the corrective leveler.

Along with coil set and crossbow, a Precision Corrective Leveler can remove wavy edges, center buckles, and twisted coil strip.

|

|

|

|

| Center Buckle |

Cross Bow |

Coil Set |

Edge Wave |

What is the difference between a Precision Corrective leveler, a Coil Straightener and a Precision Coil Straightener?

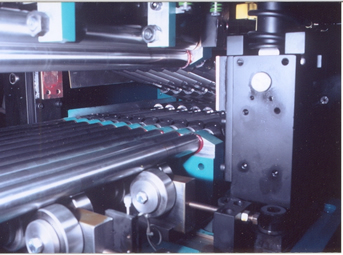

B&K Precision Corrective Roller Levelers utilize a series of relatively small closely spaced leveler rolls that incorporate roller back-ups to prevent deflection. This arrangement allows the material to be worked beyond the yield point to remove trapped material stresses. The result is material that is more stable so that flat sheets remain flat. Precision Corrective Roller Levelers also have flights of adjustable back-up rollers that are utilized to deliberately flex or bend the small diameter leveler work rolls to remove shape defects such as wavy edges or center buckles. Coil Straighteners work the material to approximately 20-30 percent of its permanent yield and are only capable of removing coil set. Precision Coil Straighteners work the material to approximately 80 percent of its permanent yield. Most Precision Coil Straighteners can remove coil set and crossbow.

Roller back-ups are multiple sets of narrow rollers spaced evenly across the face of the work roll.

To corrective level material, flights of adjustable back-up rollers are utilized to deliberately flex or bend the small diameter leveler work rolls. These back-up rolls are adjustable in order to control the deflection of the work rolls and thus how and where the material is worked. When the material is passed through the leveler head, the area of the leveler work rolls that is flexed stretches the material fibers. By selectively bending the work rolls and stretching the material that is tight eliminates the loose areas. (Wavy edges or center buckles)

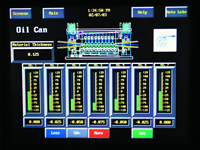

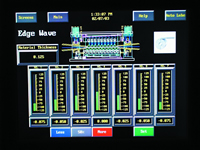

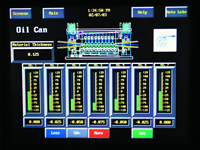

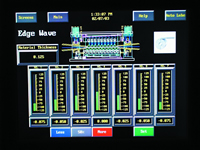

Touchscreen controlled adjustments of all normally required operator settings such as back-up roll flight positioning, upper work roll depth and angle of engagement is standard. A help screen has been integrated to allow the operator a base reference setting based on incoming material surface conditions.

|

|

| Oil Can |

Edge Wave |

The material thickness range and the materials yield point determine the Roller Leveler work roll diameter.

The engineering group at B&K can assist you to determine the proper Precision Corrective Leveler. To speak with an application engineer call 1-800-247-2645.

B&K Precision Corrective Levelers can be installed in a new Press Feed Line or retrofitted into an existing Press Feed System to precisely control flatness of your finished parts.

A Leveler that has multiple sets of narrow back-ups rollers spaced evenly across the face of the work roll is considered a 4-HI Precision Corrective Leveler. Generally a 4-HI Precision Corrective Leveler is utilized when the material surface finish is not critical.

Over time, the backup rollers may produce a mark on the work rolls, which can be transferred to the surface of the material. To prevent this, another set of full width intermediate rolls is placed between the upper work rolls and the upper back-up flights in the 5-High. In the 6-High leveler configuration, a set of full width intermediate rolls is placed between the work rolls and the back-up flights for both the top and bottom sections. These roll(s) help to distribute the pressure of the back-up rollers across the surface of the work roll.

This setup is used when top surface-critical materials are being processed: soft aluminum, single-sided polished stainless, and pre-painted one side, for example.

This setup is used when top and bottom surface-critical materials are being processed: examples of this include soft aluminum, polished stainless both sides, and pre-painted both sides.

While some Leveler manufactures shy away from HSLA materials, B&K Precision HSLA Roller Levelers have been specifically designed to meet the challenge.

YES, B&K Precision HSLA Roller Levelers utilize a series of relatively small closely spaced leveler rolls that incorporate roller back-ups to prevent deflection. This arrangement allows the material to be worked beyond the yield point to remove trapped material stresses. The result is material that is more stable so that part quality is consistent. Flat parts stay flat and round parts stay round.

A B&K® Precision corrective Leveler is equipped with a user-friendly touchscreen incorporates a complete maintenance manual as well as an operator thread-up training manual and a complete diagnostics package. All lubrication requirements of the Precision Corrective Leveler are handled automatically. An automatic grease system for the bearings and an automatic oil system for the gears and U-joints are provided.

No, an easy 3 step process allows is all that is required to attain easy access to change the work rolls, work roll bearings or the back-up rolls.

- Lift the leveler head to the open position and block the upper rollers. Note: All B&K levelers have a high-rise head as standard.

- Pivot the operator control will out of the way allowing easy access to the side roller housings.

- Remove two bolts and 2 locator pins to remove the side roller housing.

Access to clean the work rolls is always a concern in corrective levelers due to the number of rolls within the machine. Levelers quite often process critical finish materials and any foreign matter on the works rolls quickly transfers to the end product resulting in excess scrap material being produced. B&K, understanding that down time to clean the rolls and scrap material are very costly to the customer, incorporates a powered high rise head into ever leveler produced. This feature allows the head of the leveler to power open and provide 6" of clearance for quick and easy access to clean the rolls.

Precision Levelers for the 21st Century

Precision Levelers for the 21st Century